Why Is It So Critical to Install Stainless Steel Bolts In Aluminum Correctly?

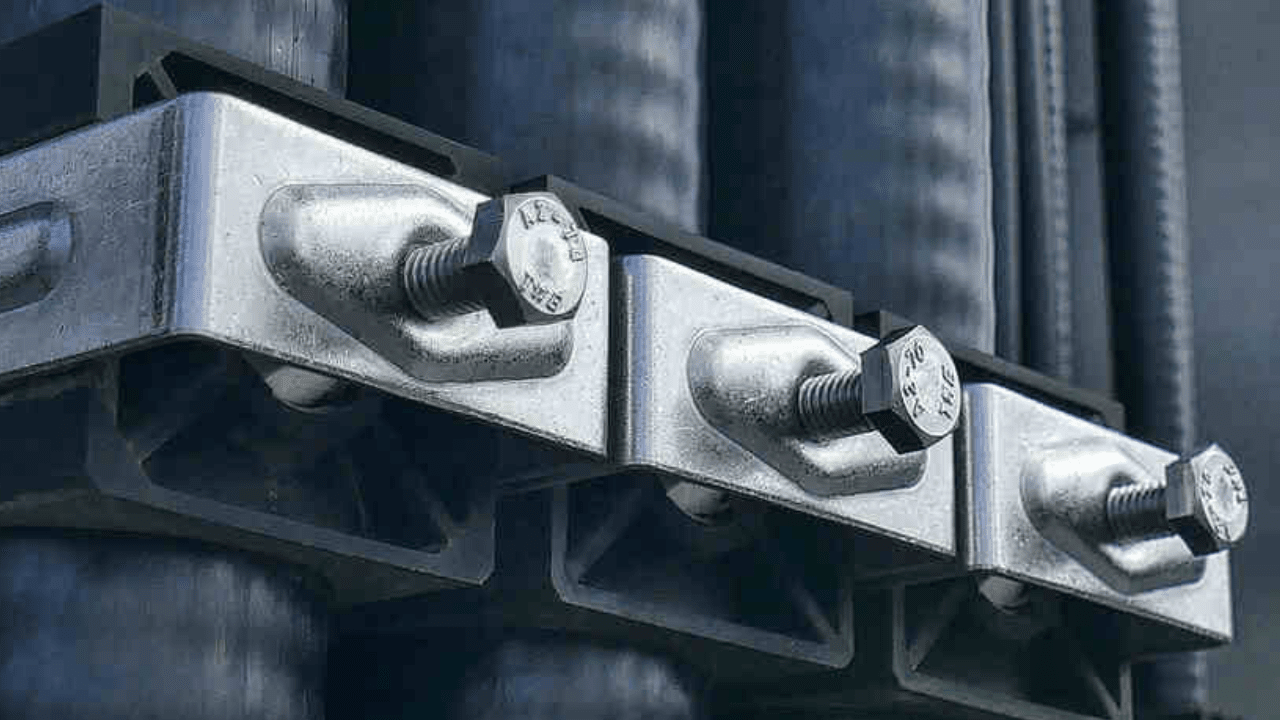

Installing stainless steel bolts with aluminum is an ordinary practice in different enterprises, providing a mix of power, toughness, and corrosion resistance. This matching presents explicit difficulties because of the distinct nature of the substances, requiring careful consideration throughout the arrangement to guarantee the best overall execution and sturdiness of the joint. Stainless steel, perceived for its strength and corrosion resistance, supplements aluminum’s lightweight and flexible properties, making it an incredible choice for outdoor applications, marine conditions, and underlying structures.

However, the interplay between stainless steel and aluminum can result in galvanic corrosion, wherein the aluminum corrodes preferentially in the presence of an electrolyte. Moreover, variations in thermal enlargement fees between the two materials can create mechanical pressure and compromise joint integrity if not managed properly. To deal with those demanding situations, proper installation techniques of stainless bolts in aluminum are essential, such as the usage of insulating substances, protective coatings, and adherence to recommended torque specifications.

Significance of Right Installation Of Stainless Steel Bolts In Aluminum

This article explores the reasons why proper installation is essential and the first-class practices to achieve it.

Managing Thermal Expansion

Proper installation of stainless steel bolts in aluminum is essential to managing their different thermal expansion and stopping stress and joint failure. Flexible joints with oversized holes or slots accommodate movement, while suitable fastening strategies, like lock washers or thread-locking compounds, maintain joint integrity. The right set-up guarantees that enlargement and contraction do not cause mechanical stress, retaining the structural balance and longevity of the assembly at varying temperatures.

Stopping Galvanic Corrosion

The right installation of steel bolts in aluminum is important to forestall galvanic corrosion. The use of isolation substances like nylon washers and plastic sleeves, applying protective coatings, and considering cathodic safety are key measures. These practices prevent direct steel contact and electric conductivity, appreciably lowering the risk of corrosion. The right installation thus guarantees the sturdiness and longevity of the assembly in outdoor environments.

Ensuring Mechanical Compatibility

The right installation of stainless steel bolts in aluminum is important for ensuring mechanical compatibility between the 2 substances. By adhering to precise torque specs and the use of appropriate thread embeds, the opportunity of harm to aluminum threads or twisting of parts is limited. This ensures that the joint keeps up with its primary trustworthiness and load-bearing capacity over the long haul. Legitimate establishments, consequently, assume a significant role in streamlining the presentation and sturdiness of assemblies connected with stainless steel and aluminum.

Improving Corrosion Resistance

The right installation of stainless steel bolts in aluminum is fundamental for helping consumption resistance in outside conditions. By following the right installation procedures, along with the use of defensive coatings like anodizing and utilizing detachment substances to save you from galvanic corrosion, the sturdiness of the joint is extensively improved. This ensures that the assembly stays solid and strong contrary to corrosion, subsequently keeping up with its primary respectability and capacity throughout the long term, even in harsh environmental circumstances.

Improving Structural Integrity

Proper installation of stainless steel bolts in aluminum is vital for boosting structural integrity. The joint’s stability and sturdiness are optimized by ensuring specific alignment, distributing masses frivolously, and using the correct variety and form of fasteners. Proper installation mitigates the danger of premature put-on, deformation, or failure, thereby making sure that the meeting maintains its structural integrity over its lifespan. This contributes to the general protection and reliability of systems related to stainless steel and aluminum components.

Summary

The right installation of stainless steel bolts in aluminum is critical to mitigating the dangers related to galvanic corrosion, differential thermal growth, and mechanical incompatibilities. By using isolation techniques, shielding coatings, and cautious design concerns, you may improve the sturdiness and reliability of the joints. Normal protection and suitable fabric selection similarly ensure the long-term performance of the shape. Adhering to those satisfactory practices no longer most effectively extends the lifespan of the meeting, but additionally guarantees safety and functionality in annoying outdoor environments.