In contrast to variable-speed compressors, fixed-speed compressors either run at total capacity or shut off. They are appropriate for various uses where a consistent need for compressed air exists.

As implied by their name, fix-speed air compressors pressurize and draw in air by supplying a fixed or constant voltage supply to the motor, which in turn rotates the screws at a consistent speed. Even when there isn’t much weight, your machine always operates at full throttle because it has a set-speed compressor.

With this type of compressor, the pressure in the storage tank drops as the compressed air is used up. When that pressure reaches a specific level, the machine restarts to pump more air into the tank fixed-speed compressors run continuously at maximum speed, generating more air than is required while squandering energy.

Guide for Selecting Perfect Air Compressor

Consequently, the following is a quick shopping guide to help you decide which air compressor will best meet your unique requirements:

Compressor Grades

Compressors are divided into various groups according to their capacity and intended usage. You have to be aware of them. Consumer-grade compressors are made for the house or a small garage workshop and can manage low pressures while often only using one tool at a time.

- Small tools like nail guns and roadside repair tools can be used on construction sites thanks to contractor-grade compressors. They can be carried around, occasionally wheeled, or mounted on a cart or small car.

- Commercial air compressors produce a steady stream of compressed air and are more powerful and feature-rich. These compressors are used in many different industries, including oil rigs, ships, and manufacturing floors.

Types of Air Compressors

Single Stage: Despite their small size and low capacity, single-stage air compressors can be moved manually. These are employed in homes and small businesses for tasks like airbrushing.

Double Stage: In factories and garages, two-stage air compressors are employed, and they can power several air tools simultaneously. These varieties cost more because they have storage tanks and double the air compression.

The Capacity of Air Compressors

The capacity and delivery of the best air compressor will be impacted by these factors. A higher PSI results in more compressed air for a given tank size. The greatest air delivery rate; while using more tools, a higher CFM is more beneficial. The power output of the compressor motor. More horsepower results in higher PSI.

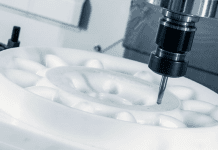

Manufacturing of Fixed-Speed Screw Compressors

Metal Sheet Cutting

Utilizing a laser cutter to cut the sheet metal into the required shapes and sizes is the first step in the manufacturing process.

Forming

After that, a machine is used to bend the sheet metal into the necessary forms, ensuring the accuracy and precision of each component.

Painting

After being produced and given time to dry, the components are painted to provide a smooth, strong, corrosion-resistant surface.

Assembling

After that, the motor and oil-gas separator are combined to provide the compressor with the power and effectiveness it needs to function.

Finalize Assembly

The components are integrated into the compressor to guarantee that everything works together as completely.

Quality Assurance

Each compressor is then checked and tested to ensure it is in good working order and conforms to all standards before being sent.

Packaging

High-quality packing materials are used to protect the compressors during transport and ensure that they arrive at their destination in good condition.

Dispatch

To ensure that the compressors are delivered on schedule, with complete tracking and insurance coverage, they work with reputable logistics partners.

Final Thoughts

Fixed-frequency screw compressors are recognized for their high reliability, dependability, and durability. Because they also have lower operating costs than other types of air compressors, they are a cost-effective option for many businesses. We just hope that this in-depth explanation of the fixed-speed compressor would be sufficient as well as interesting to read for you.